Menu

Divisions

Explore our website to discover the world of textiles crafted with precision, expertise, and a touch of tradition.

Spinning

Suryavarada Spinning Mills Limited is a pioneering force in the spinning industry, renowned for crafting top-tier yarns that anchor our diverse textile product range. Our Unit – I, with 30,000 spindles, produces over 100 tons of premium cotton yarn daily, powered by advanced machinery from LMW Coimbatore, RIETER Switzerland, and TRUTZSCHLER Germany. Our spinning plant integrates auto-control humidification and waste collection systems, monitored by the Ring Data System for optimal efficiency. Our sought-after knitting yarn is distributed in key Indian markets like Tirupur, Kolkata, and Kanpur, symbolizing our commitment to quality, innovation, and technological prowess.

Weaving

In our weaving division near Coimbatore, Tamil Nadu, skilled artisans operate 135 Sulzer wider width Jumbo looms and 18 Sulzer Airjet looms, specializing in fabric up to 140 inches in the 500 TC to 1000 TC range. With plans for jacquard looms for high-quality home textiles, we offer options with 2, 4, and 8 pick insertions, achieving a maximum warp density of 110 ends/cm (280 ends/inch) and warp counts up to 100s Ne. Additionally, 18 specially modified Dobby looms and 85 jumbo looms cater to ultra-fine count weaving and industrial textiles, respectively. Our commitment is to deliver exceptional quality and versatility in fabric creation.

Knitting

Suryavarada Spinning Mills Limited’s knitting division seamlessly combines traditional craftsmanship with modern technology, offering a diverse range of comfortable knitwear from basic to intricate patterns. Established in 1995 near Coimbatore, Tamil Nadu, the division produces Grey Single Jersey, Interlock, and Rib fabrics (20″ to 36″ diameter) using 150 knitting machines from Pailung and Mayer & Cie. With a production capacity of 3,00,000 meters per year, we specialize in various knit constructions, utilize Auto Striper machines for yarn-dyed fabrics, and ensure 100% inspection of fabric rolls under a 4 Points Inspection System. Our commitment to flexibility is reflected in machine specifications ranging from 20″ to 36″ diameter and 24/28GG. At Suryavarada, we knit excellence into every fabric strand.

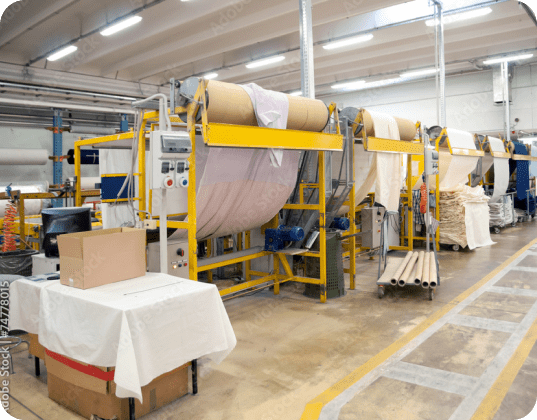

Processing

Our Processing Division in Coimbatore, Tamil Nadu, upholds the highest standards of textile quality and durability. Using advanced techniques, we enhance texture, color, and finish, delivering products that endure over time. With an in-house spinning advantage, we provide superior quality products with shorter lead times.

Processing 12 tons of knitted fabric daily, our product range includes Single Jerseys, Ribs, Interlocks, Piques, Honey Combs, and various blends. Our facility is equipped with top-notch machinery, including the THESIS dyeing machine from Germany and the LAFER compacting machine from Italy.

In response to the demands of top-tier apparel brands, we continually introduce new, value-added products with performance finishes. Our commitment to excellence ensures that customers receive the best from our Processing Division.

Garments

Our company has established a cutting-edge Garment Unit near Coimbatore, Tamil Nadu, dedicated to the production of knitted garments. Operating under the names Fashion Threads and Accel Apparels, the unit boasts a capacity to manufacture 1.5 million and 4.5 million pieces per year, respectively.

Our Garment facility is outfitted with state-of-the-art equipment and robust systems, ensuring seamless production of both inner and outerwear. We prioritize top-quality raw materials, utilize modern machinery, and employ efficient production techniques to deliver premium products at competitive prices.

With CAD CAM facilities featuring Auto Cutting, we ensure fast and accurate garment construction. Additionally, our in-house TAJIMA Embroidery machine adds value to our products.

We take pride in our certifications, including Organic, PIMA, Fairtrade, and BCIP, spanning the entire value chain. Our commitment to compliance extends to fully meeting international regulations on manufacturing practices. At every step, we strive for excellence in crafting garments that meet the highest standards of quality and sustainability.